VAKPOOL DL-M – Oligomers Removing-Chelating Dispersant for All Kinds of Fabrics

UniVOOK Chemical’s VAKPOOL DL-M is a highly advanced oligomer removing-chelating dispersant designed for comprehensive fabric care. This dual-purpose formula excels in textile processing, where it removes harmful oligomers and acts as a powerful chelating agent, preventing fabric discoloration and enhancing material quality. Oligomer removal is crucial for maintaining the integrity and appearance of fabrics, making VAKPOOL DL-M essential for manufacturers aiming for top-tier fabric standards. With its versatile application across various fabric types, VAKPOOL DL-M stands out as a pivotal solution in textile maintenance and care.

Product Description

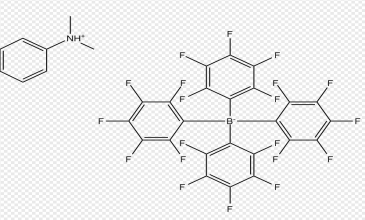

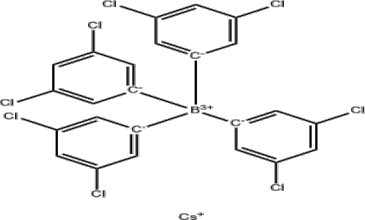

Chemical Composition and Molecular Function

The Oligomers Removing and Chelating Dispersant, VAKPOOL DL-M, is a highly specialized chemical formulation aimed at enhancing fabric processing. The compound is designed to tackle specific challenges associated with the polymer stability during the dyeing processes of synthetic fibers like polyester. At a molecular level, VAKPOOL DL-M works by targeting and breaking down oligomers, which are small polymer fragments that can lead to sedimentation issues in dye baths. Furthermore, its chelating properties help in binding metal ions that could otherwise catalyze unwanted polymerization reactions, thus ensuring smoother and more uniform dyeing.

Properties for Versatility

VAKPOOL DL-M is engineered to be effective across a broad range of fabric types, not just limited to synthetics. Its molecular structure allows it to interact beneficially with various fabric compositions, ensuring that it can prevent sedimentation and enhance dye uptake uniformly. This makes it suitable for both continuous and discontinuous textile processing methods, providing flexibility in its application across different fabric manufacturing and treatment scenarios.

Key Features

Adaptability Across Conditions

One of the standout features of VAKPOOL DL-M is its stability under various conditions. It is effective in any pH environment and can withstand high temperatures, making it ideal for high-temperature dyeing processes. This stability helps in maintaining consistent performance without the degradation of the compound or loss of efficacy, which is critical during extensive industrial fabric dyeing operations.

Specialized Applications in Textile Processing

VAKPOOL DL-M serves multiple roles in textile processing:

- As an anti-sedimentation agent, it is crucial for polyester fiber dyeing, where it prevents the settling of polymers and other particulate matter.

- It enhances the cleanliness of dyeing equipment by preventing the build-up of residues, thereby reducing downtime for maintenance and increasing operational efficiency.

- In processes involving tight fabric configurations, such as bobbin yarn and warp shaft dyeing, VAKPOOL DL-M improves bath circulation and filtration, directly addressing common challenges in these applications.

Ease of Use and Enhanced Performance

VAKPOOL DL-M is not only useful for dyeing but also effective in stripping treatments, which involve the removal of unwanted coloration or preparation of fabrics for dyeing. It enhances the dispersion performance of dyes, preventing issues related to reduced solubility and ensuring deeper, more vibrant colors. Additionally, it addresses specific problems such as staining caused by titanium dioxide in the dyeing of polyamide fibers, making it a versatile tool in achieving aesthetic and quality standards.

Complementary Products

For comprehensive fabric care, consider combining VAKPOOL DL-M with our new product, Phenol Yellowing (BHT) Inhibitor Lutas MGB, which is specifically formulated for nylon and its blends with elastic fibers. This inhibitor is designed to prevent yellowing caused by phenolic compounds, ensuring that the fabrics retain their brightness and color integrity over time.

Benefits

Enhanced Fabric Quality

VAKPOOL DL-M plays a critical role in improving fabric quality by effectively removing unwanted oligomers. These oligomers, if left untreated, can lead to rough textures and uneven dyeing. By eliminating these substances, VAKPOOL DL-M ensures smoother, more uniform fabrics, which are essential for high-quality textile products.

Stain and Discoloration Prevention

This dispersant excels in preventing the common issues of fabric staining and discoloration during the dyeing process. Its chelating properties help in binding harmful metal ions that can cause these undesirable effects, thereby preserving the original colors and preventing any blemishes on the fabric surface.

Longevity and Appearance

The integrity of fabrics is markedly improved with the use of VAKPOOL DL-M. It not only extends the life of the fabric by preventing harmful deposits and fiber degradation but also enhances the overall appearance, ensuring that fabrics look newer for longer.

Versatility Across Fabric Types

VAKPOOL DL-M is suitable for use with a wide range of fabric types, including sensitive materials. Its gentle yet effective action makes it a preferred choice for manufacturers dealing with diverse textile products, from heavy-duty industrial fabrics to delicate apparel.

Performance

Efficacy Studies and Test Results

Research and development tests have consistently demonstrated the efficacy of VAKPOOL DL-M in removing oligomers and improving dye uniformity. Tests indicate a significant reduction in sedimentation during dyeing processes compared to other market alternatives.

Market Comparisons

VAKPOOL DL-M stands out in the market due to its dual functionality as both an oligomer remover and a chelating dispersant. Comparative studies show that while other products might address one issue, VAKPOOL DL-M efficiently resolves multiple challenges in fabric processing, offering a comprehensive solution.

Customer Testimonials

Feedback from industry users underscores the effectiveness of VAKPOOL DL-M. One notable testimonial from a large textile manufacturer cites how switching to VAKPOOL DL-M reduced their need for repeat dyeing processes, leading to cost savings and improved production timelines. Case studies also highlight its impact on enhancing fabric quality in high-stress environments like sports apparel manufacturing, where fabric integrity and color stability are crucial.

Safety and Handling

Safety Precautions and Protective Equipment

When handling VAKPOOL DL-M, it is essential to use appropriate safety gear. Workers should wear protective clothing, gloves, eye protection, and, if necessary, a face mask to prevent any direct contact with the skin or eyes. Ensuring proper ventilation in the working area is also crucial to avoid inhalation of any fumes or aerosols that might be generated.

First Aid Measures

In case of accidental exposure:

- Skin Contact: Immediately wash the affected area with plenty of water for at least 15 minutes. Remove contaminated clothing.

- Eye Contact: Rinse immediately with plenty of water, also under the eyelids, for at least 15 minutes. Seek medical attention if irritation persists.

- Inhalation: Move the person to fresh air immediately. If symptoms persist, seek medical advice.

- Ingestion: Rinse mouth with water (only if the person is conscious). Do not induce vomiting and seek medical assistance immediately.

Storage and Disposal Recommendations

VAKPOOL DL-M should be stored in a cool, dry place away from heat and direct sunlight within a temperature range of 3-40°C. If frozen at 0°C, the product can be thawed and used without any loss of performance. Disposal of the product and any contaminated packaging should comply with local environmental regulations to prevent environmental contamination.

Environmental Impact

Biodegradability and Environmental Safety

VAKPOOL DL-M is designed with environmental safety in mind. The product is biodegradable, which means it breaks down into non-harmful components after use, reducing its environmental footprint.

Regulatory Compliance

This product complies with major regulatory frameworks such as REACH and GHS, ensuring that it meets safety, health, and environmental protection standards. Compliance with these regulations confirms that VAKPOOL DL-M is manufactured, handled, and used safely.

Environmental Precautions

To minimize environmental impact, it is important to avoid releasing large quantities of this product into the environment. Facilities using VAKPOOL DL-M should ensure that effluent treatments are in place to treat water that may contain traces of this chemical before discharging it into water bodies. This helps prevent potential pollution and promotes a healthier ecosystem.

Final Thoughts

VAKPOOL DL-M from UniVOOK Chemical becomes an important solution for the textile industry. Provides superior performance in fabric care and maintenance. Its ability to remove oligomers and prevent staining improves fabric quality. Its biodegradability and compliance with environmental laws underscore its commitment to sustainable development. By integrating safety protocols and ensuring versatility across various fabric types, VAKPOOL DL-M not only meets but exceeds industry standards. For manufacturers looking to optimize fabric processing, increase product life and adhere to environmental best practices. This product is a valuable asset, making it an important choice for forward-thinking textile operations.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs