5-Hydroxymethylfurfurale as a Monomer to Synthesize Biodegradable Polymers

Introduction to the urgent need for biodegradable polymers stems from the escalating environmental concerns associated with conventional plastics. As society seeks sustainable alternatives, 5-Hydroxymethylfurfural (HMF) emerges as a promising candidate. Derived from sugars, HMF acts as a pivotal bridge between biomass and furan-based chemicals, facilitating the transformation of renewable resources into valuable organic compounds. At UniVOOK Chemical, we champion innovation across 19 diverse industries worldwide, offering solutions that empower our customers to distinguish their products in an evolving market landscape.

Chemistry of 5-Hydroxymethylfurfural (HMF)

Molecular Structure and Properties of HMF

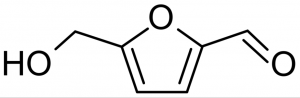

5-Hydroxymethylfurfural (HMF) possesses a molecular formula of C6H6O3 and a molecular weight of 126.11 g/mol. Its molecular structure features a furan ring with a hydroxymethyl group (-CH2OH) at position 5 and an aldehyde group (-CHO) at position 2. These structural attributes grant HMF exceptional reactivity and solubility across a broad spectrum of solvents. Moreover, HMF demonstrates remarkable heat resistance and stability, rendering it highly desirable for polymerization reactions.

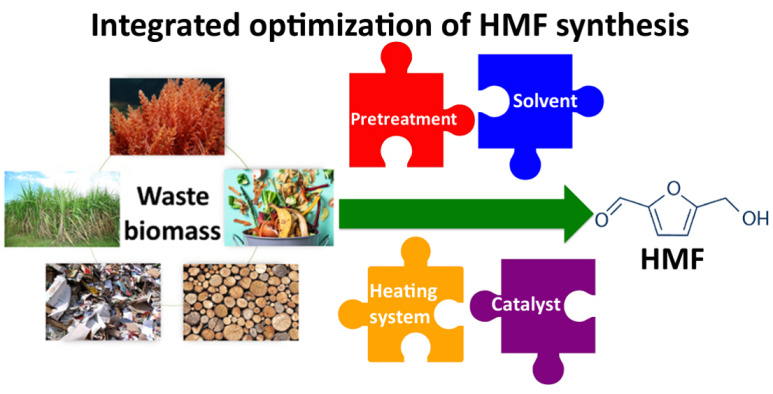

Synthesis Methods of HMF

HMF synthesis entails diverse pathways utilizing biomass-derived carbohydrates like glucose, fructose, or cellulose. Acid-catalyzed dehydration of sugars represents a prevalent method, wherein hydroxyl groups undergo removal, yielding furanic compounds that ultimately evolve into HMF. Alternatively, enzymatic or heterogeneous catalysis routes offer greener, more selective pathways for HMF synthesis. These methodologies efficiently convert renewable biomass into HMF, thus fostering the sustainability of the overall process.

Reactivity of HMF in Polymerization Reactions

HMF manifests versatile reactivity in polymerization reactions, enabling the synthesis of a vast array of polymers with tailored properties. Its reactive functional groups, including the aldehyde and hydroxymethyl groups, facilitate participation in various polymerization mechanisms such as condensation, addition, or ring-opening polymerization. By manipulating reaction conditions and catalysts, researchers can modulate HMF polymerization to achieve desired molecular weights, structures, and functionalities. Such versatility positions HMF as an appealing monomer for synthesizing biodegradable polymers with diverse applications.

Biodegradable Polymers

Definition and Importance of Biodegradability

Biodegradable polymers undergo degradation through biological processes catalyzed by microorganisms, enzymes, or other living organisms. Unlike conventional plastics, which persist for extensive periods in the environment, biodegradable polymers offer a sustainable remedy to the escalating plastic pollution crisis. By decomposing into harmless byproducts such as water, carbon dioxide, and biomass, biodegradable polymers mitigate the environmental repercussions of plastic waste and contribute to fostering a circular economy.

Current Methods and Materials Used in Biodegradable Polymer Synthesis

Synthesizing biodegradable polymers involves employing various methods and materials, encompassing natural polymers like starch, cellulose, and proteins, alongside synthetic polymers derived from renewable resources or petrochemicals. Common techniques include polymerization, polycondensation, and blending with additives or fillers to enhance biodegradability. Tailoring biodegradable polymers to specific applications necessitates adjustments in chemical composition, molecular weight, and degradation kinetics.

Challenges and Limitations of Existing Biodegradable Polymers

Despite their environmental benefits, prevailing biodegradable polymers encounter several challenges and limitations. These encompass restricted mechanical properties, inadequate processability, and elevated production costs vis-à-vis conventional plastics. Additionally, the degradation rate of biodegradable polymers may fluctuate contingent upon environmental factors like temperature, moisture, and microbial activity. Overcoming these challenges mandates further research and development efforts to enhance the performance, scalability, and cost-effectiveness of biodegradable polymer materials, thereby fostering widespread adoption across diverse industries.

Properties and Applications of HMF-based Biodegradable Polymers

Overview of Polymerization Methods Utilizing HMF

5-Hydroxymethylfurfural (HMF) serves as a cornerstone in the creation of renewable and sustainable organic chemicals. Its applications span across various industries, including food and beverage, materials, pharmaceuticals, and biofuels. HMF’s versatility and reactive functional groups make it an ideal candidate for polymerization, enabling the development of biobased polymers with enhanced properties.

Mechanical Properties of HMF-based Polymers

HMF is derived from sugars like glucose and fructose through dehydration reactions, aligning with sustainable chemistry practices. Its structural characteristics enable diverse chemical transformations, serving as an intermediate in valuable chemicals and materials synthesis. Originating from renewable biomass, HMF emphasizes eco-friendliness, appealing to environmentally conscious industries. Its role as a sweetener precursor promotes natural alternatives, supporting sustainability and health awareness. Additionally, HMF’s antioxidant properties are valuable for food preservation and cosmetics, safeguarding against oxidative degradation and prolonging shelf life.

Potential Applications in Various Industries

HMF serves as a substitute for formaldehyde in phenolic resin production, reducing reliance on petroleum-based chemicals. It contributes to furan resin, known for heat resistance and electrical insulation in various industrial applications. In medicine, HMF and its derivatives treat inflammation, act as antioxidants, and enhance memory. In the food industry, HMF enhances flavor profiles, particularly in fried foods, as a natural alternative to synthetic additives. HMF and its derivatives replace petroleum fuels, aiding in the development of sustainable fuel sources. As a monomer, HMF enables the synthesis of biodegradable polymer materials, suitable for applications in synthetic fibers, rubber, and casting industries, promoting eco-friendly materials adoption.

Environmental Impact and Sustainability

Environmental Advantages of HMF-based Biodegradable Polymers

HMF-based biodegradable polymers offer notable environmental benefits. Originating from renewable biomass sources, these polymers decrease reliance on finite fossil fuels. Their biodegradability ensures they decompose into harmless components, minimizing environmental pollution and waste accumulation. Advocating for HMF-based polymers can significantly reduce industrial carbon footprints and bolster overall sustainability efforts.

Contrasting with Traditional Polymers and Biodegradable Alternatives

In comparison to conventional petroleum-derived polymers, HMF-based biodegradable alternatives present a sustainable choice. Unlike their fossil fuel-based counterparts, they diminish environmental persistence and resource depletion. Additionally, when compared to other biodegradable options such as corn or soy-based polymers, HMF-based polymers may exhibit a smaller environmental footprint due to their diverse biomass sourcing and potentially more efficient manufacturing processes.

Challenges and Prospects for the Future

Despite their environmental advantages, HMF-based biodegradable polymers encounter challenges in scalability, cost-effectiveness, and technological advancement. Collaboration among industry stakeholders, policymakers, and researchers is essential to refine production methods and enhance material properties. Increasing public awareness and incentivizing adoption can stimulate market growth. Continued research and innovation hold the promise of overcoming these hurdles and fully harnessing the potential of HMF-based biodegradable polymers for environmental sustainability.

Final Thoughts

5-Hydroxymethylfurfural (HMF) emerges as a promising monomer for crafting biodegradable polymers suitable for a myriad of applications. Its sourcing from renewable biomass aligns harmoniously with sustainability objectives, while its adaptable chemistry facilitates the formulation of custom polymers. HMF-based polymers not only serve as eco-friendly alternatives to traditional petroleum-derived materials but also aid in waste minimization efforts. Additionally, HMF finds utility across diverse industries, including pharmaceuticals and food additives, underscoring its versatility and broad adoption potential. With ongoing endeavors to refine production techniques and tackle obstacles, HMF-based biodegradable polymers stand as a pivotal means of championing environmental sustainability and fostering a greener tomorrow.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs